How to identify the quality of aluminum alloy doors and windows?

2024-10-25

Aluminum alloy doors and windows are favored by consumers for their unique advantages of light weight, high strength, corrosion resistance, and extrusion into various new and complex cross-section materials, and there is a trend to gradually replace plastic steel, wood and other materials doors and windows.

In fact, to distinguish the quality of aluminum alloy doors and windows, it is just to look at the two hands and listen to a few points. The specific identification of aluminum alloy doors and windows is as follows:

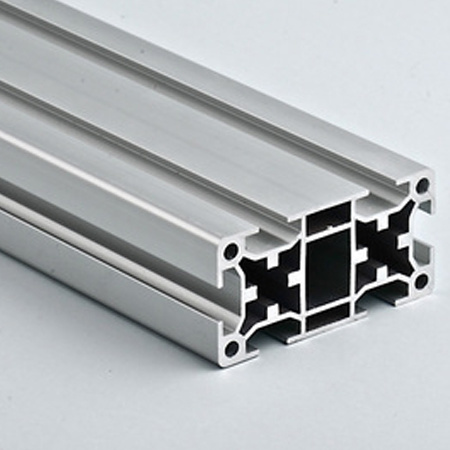

Profile thickness

Currently commonly used 70 and 90 series aluminum profiles, the national standard wall thickness is more than 1.2mm, and the wall thickness of high-quality aluminum profiles is 1.2mm~2.0mm.

Oxidation degree

How to view the degree of oxidation of special-shaped materials?In fact, it is very simple, that is, when choosing and purchasing the surface of the profile, gently scratch it, and then see if the surface of the oxide film can be wiped off after scratching.Warm reminder, this test should not be carried out on the sample window, it can be carried out on the materials displayed by the merchant.

Contour color light

Under normal circumstances, the cross-section color of high-quality aluminum profiles is silver-white and the texture is uniform. If the color difference on the same profile is obviously inconsistent, or the color is dark, it is not recommended to choose and purchase. It can be made of recycled aluminum or scrap aluminum.

Contour surface smoothness

The surface of high-quality aluminum profiles is flat and bright, with no depressions or protrusions. The surface of aluminum alloy doors and windows processed by large manufacturers is relatively smooth and bright. Aluminum alloy doors and windows processed in small workshops will have more or less slightly concave and convex shapes due to mechanical or raw material problems. Balcony windows made of aluminum alloy profiles are easy to oxidize and deform later.

Profile strength

When purchasing, you can bend the profile moderately by hand. If you do not bend the profile hard, you can conclude that the strength of the aluminum profile does not meet the standard.In addition, the strength of the profile is not as hard as possible. Aluminum has a certain toughness and non-rigid material. This characteristic is used to forge into different shapes, so the owner needs to identify the brand and observe carefully when buying.

Contour gloss

Aluminum alloy doors and windows avoid obvious defects such as vacuoles, ash, cracks, burrs, and flaking of profiles.If the above phenomena exist, it can be concluded that the secondary processing and molding of recycled aluminum or scrap aluminum is due to uneven texture and irregular alloy ratio, which is easy to crack and oxidize in the later stage.

Sound insulation and sealing, look at the structural principle of the profile

When purchasing aluminum alloy doors and windows, we must pay attention not only to sound insulation and sealing, but also to the construction principles, so as to avoid the use of consumers who do not understand the psychology of the goods, do not understand the goods, simplify or save the design of the sealing structure, and reduce the cost of aluminum.

The sealing process is operated by a combination of two woolen sealing methods to increase the number of sealing layers, reduce the number of sealing layers and air convection, and adopt automobile sealing tape to make the sealing performance better.

Key words:

ELEMENTX (M) SDN.BHD

Aluminum

RELATED INFORMATION

How to apply the materials for decorating the living room

2022-07-28

Can you still do this?Extend the aluminum industry chain

2021-11-09

Why should aluminum profiles be oxidized with sand surface?

2024-10-25