The charm of aluminum: A panoramic analysis from production to application

2024-10-25

Because of its excellent physical properties and wide range of applications, aluminum has become an indispensable and important material in modern industry and life.With the progress of technology and the continuous innovation of production technology, aluminum is no longer limited to traditional casting and forging, but has shown amazing application potential in aerospace, automobile manufacturing, building decoration, electronic products and many other fields.

1. Basic characteristics of aluminum

Aluminum is a lightweight metal with a density of about 2.7g/cm3, which is only one-third that of iron. This makes aluminum reduce its overall weight while still having good strength.This characteristic makes it particularly popular in the aerospace and automobile manufacturing fields, which can effectively improve fuel efficiency and reduce emissions.In addition, aluminum has good corrosion resistance, which is due to the rapid formation of a thick alumina film on its surface to protect its interior from corrosion.At the same time, aluminum also has good thermal conductivity and electrical conductivity, making it widely used in electronic equipment and heat exchangers.

2. The production process of aluminum

The production of aluminum is generally divided into two steps: bauxite refining of aluminum oxides and aluminum oxide electrolysis to reduce aluminum.First, the bauxite is calcined at high temperature to extract aluminum oxide (AlOo₃).Then, the aluminum oxide is reduced to aluminum metal through the electrolysis process.This process requires a lot of electrical energy and is usually carried out in a dedicated electrolytic cell.

The refining process of aluminum is also accompanied by a certain impurity removal process to ensure the purity of aluminum.At this stage, the use of green electricity (such as hydropower, wind power, etc.) to produce aluminum can significantly reduce the production cost of aluminum and reduce carbon emissions, which contributes to environmental protection and sustainable development.

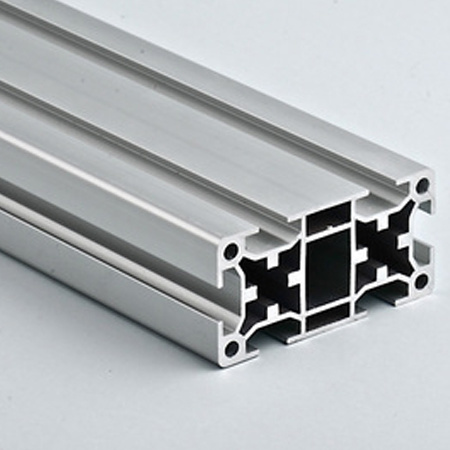

Third, the processing technology of aluminum

The processing technology of aluminum has become more and more diversified, including casting, extrusion, rolling, etc.Casting is to melt aluminum and inject it into a mold for cooling and forming, which is suitable for mass production of aluminum products of complex shapes.Extrusion is to pass the aluminum block through the mold at high temperature to form a specific cross-section of aluminum, which is widely used in construction, transportation, machinery and other fields.In addition, the aluminum rolling process can prepare thin sheets, foils, etc., which are suitable for packaging, construction and home appliance industries.

Further, aluminum can also use heat treatment processes, such as solution treatment, aging treatment, etc., to improve its mechanical properties and corrosion resistance.The combination of different alloy composition and heat treatment technology makes aluminum more widely used.

Fourth, the application field of aluminum

1. Construction and construction: Aluminum is widely used in building facades, curtain wall systems, doors and windows due to its light weight, high strength and good corrosion resistance.At the same time, the color and surface treatment of aluminum can meet various design needs, making the appearance of the building more beautiful and modern.

2. Transportation: In vehicles such as automobiles, aviation, and railways, the use of aluminum can significantly reduce the overall weight, thereby improving fuel economy and reducing emissions.Many automobile manufacturers have begun to adopt aluminum alloy body manufacturing to improve vehicle performance and safety.

3. Electrical and electronic: As an excellent conductive material, aluminum is widely used in cable conductors, heat sinks and electronic product housings.Its excellent thermal conductivity makes aluminum an ideal choice for electronic components, which can effectively prevent overheating and extend the service life of equipment.

4. Packaging materials: Because of its excellent barrier properties, aluminum foil is widely used in food, medicine and other packaging to extend the shelf life of products.Aluminum has begun to become an important alternative to traditional packaging materials.

5. The market prospects of aluminum

With the global emphasis on environmental protection and sustainable development, the aluminum market has gradually attracted attention.It is predicted that the aluminum market will continue to grow in the next few years, especially in emerging fields such as new energy vehicles and green buildings, and the application of aluminum will be more extensive.Governments around the world have also introduced policies to encourage the recycling and utilization of aluminum, thereby increasing the renewable utilization rate of aluminum.

Many companies have worked hard on product design and production technology to strengthen the green production concept of aluminum.For example, by optimizing the composition and structure of aluminum alloys, improving their performance and processability, reducing their impact on the environment, and promoting the transformation of the aluminum industry to a sustainable development model.

6. Recycling and reuse of aluminum materials

One of the major advantages of aluminum is that it can be recycled, and recycling aluminum can save up to 95% of energy.The aluminum recycling process is simple, and after sorting, cleaning, and smelting, new aluminum materials can be made.Environmental protection organizations and government agencies are actively promoting the recycling of aluminum and raising public awareness of environmental protection.Manufacturers also use their own recycling mechanisms to ensure that the aluminum materials used can be effectively reused.

Seven, the challenges faced by aluminum

Although the advantages of aluminum are obvious, there are also some challenges in the global aluminum market.First of all, the issue of carbon emissions in the aluminum production process is gradually receiving attention.Many companies have begun to explore low-carbon aluminum production technologies to reduce their environmental impact.Secondly, the competition in the international market is becoming increasingly fierce, and the rise of various alternative materials has also brought threats to the aluminum industry. Enterprises must continuously improve their technical level and innovation ability in order to be invincible.

Key words:

ELEMENTX (M) SDN.BHD

Aluminum

RELATED INFORMATION

How to apply the materials for decorating the living room

2022-07-28

Can you still do this?Extend the aluminum industry chain

2021-11-09

Why should aluminum profiles be oxidized with sand surface?

2024-10-25